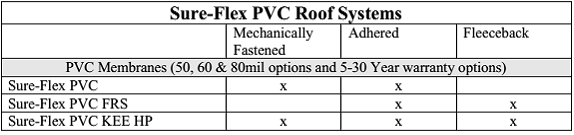

Polyvinyl chloride (PVC) is a trusted roof membrane that has been providing decades of protection North America. PVC’s popularity stems from its heat-welded seams, high reflexivity, and resistance to water, chemicals, grease, fire and punctures. Carlisle’s Sure-flex PVC’s feature Energy Star qualifications, meets or exceeds the requirements of ASTM D4434 standard specification for PVC sheet roofing, and can contribute to LEED credit requirements.

The Sure-Flex product line is one of the broadest in the industry, offering a PVC membrane for virtually any low-slope roofing specification. This includes sheets from 10-foot-wide to fiberglass reinforcement to FleeceBACK and Evaloy KEE enhancements, Carlisle has a PVC membrane that will suit your needs.

As always, if you have any questions or you would like to discuss a project where Carlisle Syntec Or Carlisle Coatings and Waterproofing may help determine your specification approach, please contact your local Luna & Associates Representative to discuss in further detail.

Archive for roofing

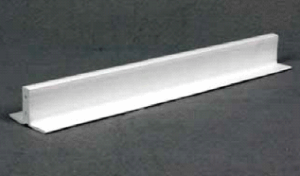

Carlisle Contour Rib: Provides the appearance of a Standing Seam Metal Roofing with the Performance of Carlisle Fleeceback TPO or PVC.

The Carlisle Contour Rib is an innovative product that combines the advantages of a single-ply system with the aesthetic appeal of a standing seam metal roof. To achieve this look, the Contour Rib is hot-air welded in a parallel pattern to the exposed surface of Fleeceback TPO or Fleeceback PVC membrane to simulate a standing seam metal roofing system.

The Contour Rib measures 1-1/4” tall and 2-1/8” wide, including the welding flanges, while the vertical profile is 3/8” thick. The rectangular rib profile design provides exceptional shadow lines for aesthetic appeal. The Contour Rib is available in 10’ lengths and dimensionally stabilized and strengthened by a fiberglass reinforcing cord that runs the length of each section. Contour Rib sections are joined together by a non-corroding fiberglass connecting pin, ensuring continuity and compatibility throughout the application.

The Contour Rib is extruded from the same weather-resistant compounds as their associated Carlisle TPO or PVC membranes, ensuring comparable weathering characteristics and an excellent color match. Colors available include white, gray, or tan.

As always, if you have any questions, please contact your local Carlisle Rep to discuss in further detail.

Hail has made its’ presence felt more and more in recent years in the Luna & Associates regions, even causing damage to typically hail resistant commercial projects. Some damage is fairly evident, and readily identified such as cuts to membrane, dented units and edge metal. Another form of damage sometimes isn’t as obvious. This would be delamination of the roofing membrane from the insulation in an adhered roofing system. This type of damage starts in small areas where hail has broken the facer and left an un-adhered void. These small voids can grow with each successive wind event and cause large delamination, years after the hail storm that initiated it. Typically this phenomenon develops when the assembly does not include a cover board.

In response to this damage, roofing manufacturers have started to offer hail coverage in their warranties. In general this warranty coverage is a good benefit to the building owner. As always, the best insurance against damage is a good design. When designing for potential hail storms designers should take the following steps:

- Use a cover board of at least ½” in thickness. Thinner cover boards have been shown to break when hit by hail. High density

polyisocyanurate products such Carlisle’s Securshield HD perform very well in this role. - Secure the top layer of cover board in adhesive. Do not mechanically attach it. Hail will split the membrane if it hits the plate

or fastener. Low rise adhesives, such as Carlisle’s Flexible FAST, are specifically designed to provide cushioning and allow for

building movement while still keeping tenacious holding power on the insulation and cover board. - Utilize a thicker membrane such as a 90 mil EPDM, 80 mil TPO or 80 mil PVC. Testing has shown that externally reinforced

membranes commonly referred to as FleeceBACK membranes, perform the best of all available membranes in this role. The

slight increase in membrane thickness provides an immense increase in puncture performance.

Be wary of those who want to “Value Engineer” out one of these steps and still offer a hail warranty. When all hail breaks loose on one of your projects, will you have more faith in the warranty to replace the damaged roof system for your client or the good design that you followed to prevent the damage in the first place?

As always, please contact your local Carlisle rep if you have any questions or would like to discuss in further detail.

Commercial Roofing Products

Other Products

Recent News

Matthew Weatherly’s Story of Success in the Roofing Industry

Chuck Wilhelmi joins Luna Associates as a Sales Representative serving Iowa and Illinois

Chuck brings a wealth of knowledge and experience to Luna with over 20 years in the building products and construction industry. Chuck was most recently employed by Beacon Building products …Read More »